A POST-PETROL ERA

FOR DIESEL ENGINES

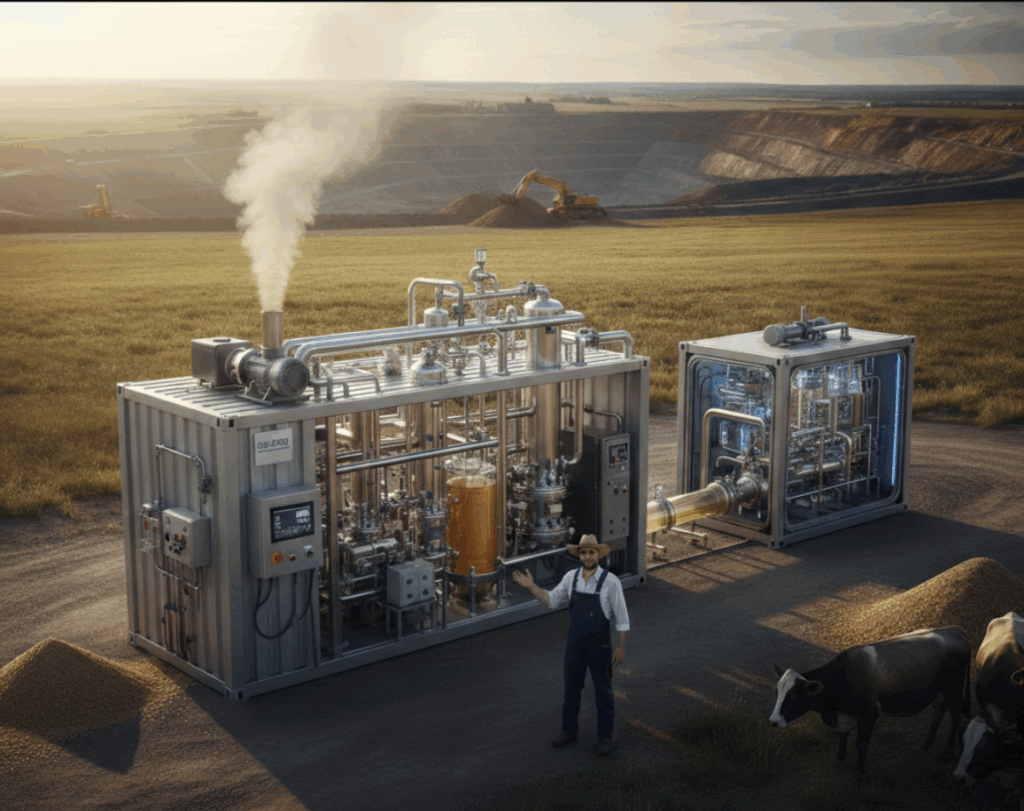

100 % Automated Process.

No Waste.

Do Not Use Water.

Delocalisable To Circular Economies In Agricultural, Transport And Food Markets.

100% Biosourceable.

Cost Competitive Against Petrodiesel. (w/o tax credit)

Low Entropic Impact Process.

Good Cold Flow Properties.

High Triglycerides Quality Tolérance (FFA, Phospholipid).

No Need To Mix With Petrodiesel.

No Engine Modification.

MODELS

PHYSICOCHEMICAL PROPERTIES OF

THE BIOFUEL PRODUCED

WITH THE MICROFACTORY

Physicochemical properties depends on the recipe used. Recipes are develop by Autarcycle Inc. to fit the nature of your triglycerides (Beef tallow, chicken tallow, soy oil, colza oil, palm oil, algea oil. etc…) and to maximized the biofuel properties to your specific uses intents.

Typical Biofuel Physicochemical Properties Produced By The Microfactory

| Heating Value (BTU/Lb) | 15 872 |

| Specific gravity @15,5 oC (g/ml) | 0,8956 |

| Viscosity @ 40 oC (cSt) | 2.2 to 6.0 |

| Pour Point (oC) | Down to -26 |

| Cloud Point (oC) | Down to -16 |

| Cetane Index | 46.5 |

| Copper Strip Corrosion | 1A |

| Oxydation stability | > 3 |

| Flash Point (oC) | < 40 |

| Carbon Residue (w%) | < 0.01 |

| Aromatics (w%) | < 0.05 |

| Acid number (mg KOH/Kg) | 0.01 |

| CSFT (sec.) | 147 |

THE CONCEPT

CLOSING THE LOOP AT THE FARM

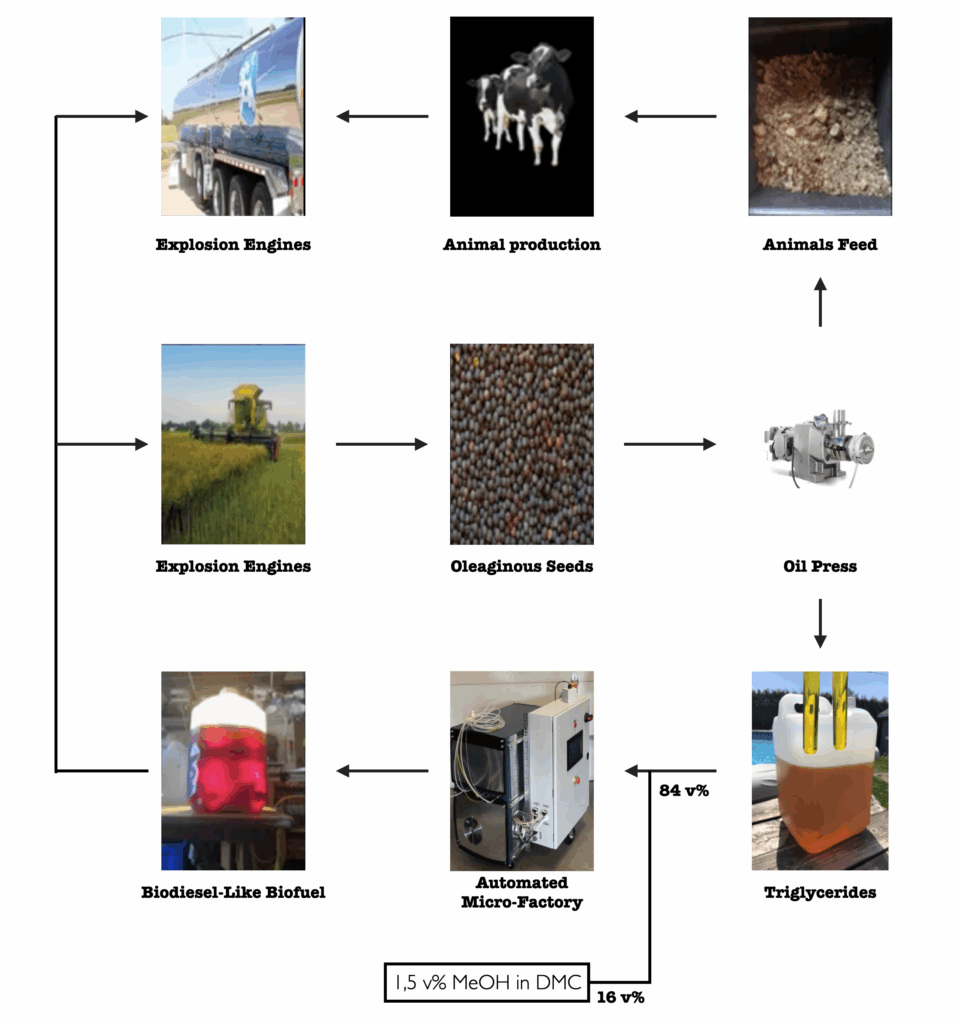

Agricultural circular biodiesel-like biofuel paradigm, closing the grain loop!

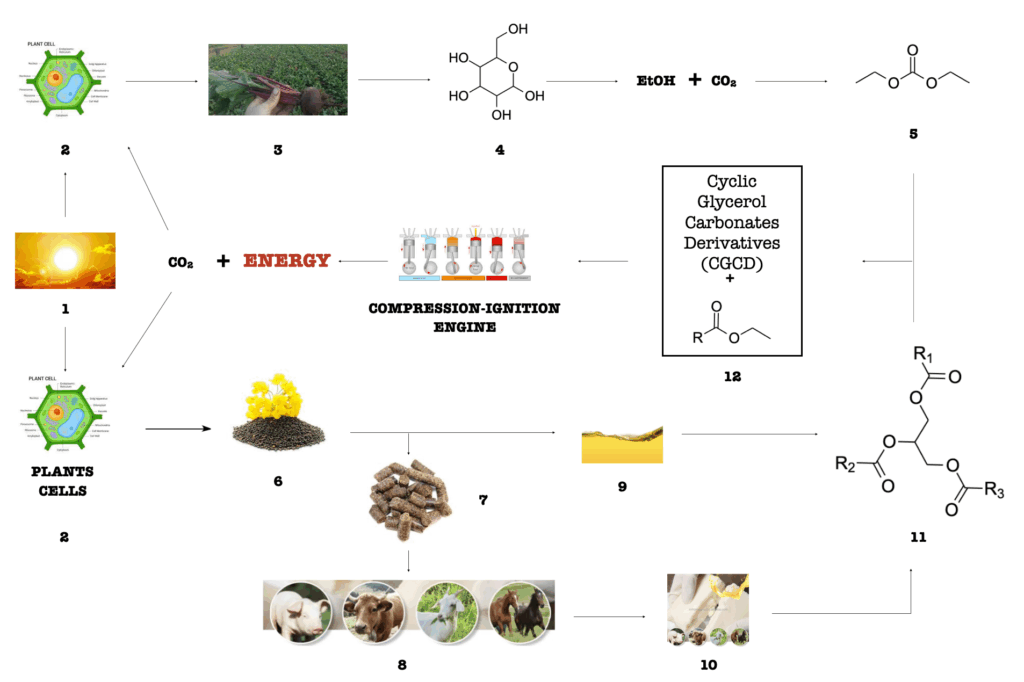

1- Sun; 2- Plant Cell; 3- Sugars; 4- Glucose; 5- Dialkyl Carbonate; 6- Oleaginous; 7- Animal Meal; 8-Meat; 9-Vegetable Oil; 10- Tallow; 11-Triglycerides; 12- Biodiesl-Like Biofuel

Recognizing that the primary source of energy on earth come from the sun. That the photons cause heat, give birth to aerial wind and marine current or can be capture by photovoltaic or photosynthetic cells. That photosynthetic cells, mainly synthesize sugars and lipids. That glucose and triglycerides are the fuel of living species. Each carbon carbon bond is a sun’s photon energy reserve made by sequestrating carbon dioxide. A few chemical transformation of these high energy containing molecules can lead to mixtures that can be used as biodiesel-like biofuels.

Firstly, alcoholic fermentation has been known to human for millennium. Since, the process has been studied and innovations have rendered possible technologies that can be automated. Thanks to Saccharomyces cerevisiae.

Secondly, alkylcarbonates are considered promising carbon dioxide capture solution and studies have demonstrated that they can be synthesized continuously from alkyl alcohol and carbon dioxide with a negative CO2 emission process, exactly what Saccaromyces cerevisiae produces from glucose.

Thirdly, automated microfactory, base on patented Autarcycle’s process, can transform triglycerides into fatty acid ester and cyclic glycerol carbonates derivatives biofuels mixtures, using alkyl carbonates. It can be totally automatized, produces no waste, uses 100% biosourceable input, is carboneutral, allows remote access, on-site production and circular economy.

Then compression-ignition engines may allow the possibility to extract the photon sun’s energy stored in the carbon-carbon bond from lipids and sugars after transforming them into a fatty acid ester and glycerol carbonates mixtures. Liberating back the sun’s energy and the carbon dioxide. Creating a neutral carbon cycle.

Knowing that transportation accounts for 25 % of our global carbon dioxide emissions, thus energy uses, and that triglycerides and glucoses are ubiquitous, delocalized automated on-site micro-machines, that can transform them into a biodiesel-like biofuel with this new carboneutral cycle biofuel possibility, is offering a chance to create a sustainable alternative to petrodiesel by creating small delocalized circular energy economy.

ENVIRONMENTAL BENEFITS

ENVIRONMENTAL BENEFITS REPORT

- Base on differents scenarios where the microfactory is intalled near the triglycerides source and where the biofuel is used locally in replacement of petro-diesel, environmental benefits expected are:

- SCENARIO A: Dialkyl Carbonate Importation To Microfactory Location

- Reduction of 1 607 kgCO2e per kL of biofuel

- 55.7% decrease in GHG emissions

- Total particulate matter (TPM), sulfur oxides (SOx), nitrogen oxides (NOx), non-methane volatile organic compounds (NMVOC) and carbon monoxide (CO) reductions.

- SCENARIO B: On Site Production Of Dialkylcarbonate

- Reduction of 2 349 kgCO2e per kL of biofuel

- 81.4% decrease in GHG emissions

- Total particulate matter (TPM), sulfur oxides (SOx), nitrogen oxides (NOx), non-methane volatile organic compounds (NMVOC) and carbon monoxide (CO) reductions.

- SCENARIO A: Dialkyl Carbonate Importation To Microfactory Location

MOTOR TESTS

CUMMINS N14 CELECT PLUS 1999

VM MOTORI R424 CRD

FAQ

Using the Biodiesel-Like Biofuel Produced by the Micro-Factory (B75 + 15% Additive Blend (DMC/GCD))

1. Do I need to modify my engine to use this fuel?

No. This formulation is a “Drop-in” fuel. This means it is chemically designed to be compatible with existing diesel technology. The high-pressure pump, injectors, and the Engine Control Unit (ECU) do not require any mechanical or software changes. The ECU’s oxygen and pressure sensors will automatically optimize the combustion cycle for this oxygenated blend. (See Ref [1])

2. How does this blend specifically reduce soot?

The addition of Glycerol Carbonate Derivatives (GCD) and DMC provides a source of “internal oxygen” during the combustion process. This prevents the formation of aromatic rings (soot precursors) at the molecular level, ensuring that carbon burns into CO2 rather than black smoke. (See Ref [2])

3. What is the role of Glycerol derivatives in this mix?

Glycerol-derived additives are sustainable, bio-based chemicals that improve the lubricity and oxygen content of the fuel. They are part of a modern circular economy approach where biodiesel by-products are upgraded into high-performance fuel additives. (See Ref [3])

4. Why is it recommended to keep the EGR and SCR systems?

Oxygenated fuels burn more efficiently but can increase peak combustion temperatures, which leads to higher NOx (Nitrogen Oxides). By keeping the EGR (which lowers temperatures) and the SCR (which treats tailpipe gases), you neutralize these invisible pollutants, making your engine cleaner than a standard Euro 6 vehicle. (See Ref [4])

5. Are there risks to fuel lines and seals?

Yes. This is the only critical maintenance point. High concentrations of biodiesel and polar additives like DMC can cause significant swelling, softening, and degradation of standard Nitrile (NBR) rubber hoses and gaskets. (See Ref [5])

- Pro Tip: Replace any rubber fuel lines with Viton (FKM) hoses, which are chemically inert to this blend.

6📊 Comparative Table of Options

| Feature | Keep All 3 Systems (EGR/SCR/DPF) | Remove DPF (Keep EGR/SCR) |

| Soot Control | Near Zero | Very Low (Invisible) |

| Modification Required | None (Drop-in) | None (Drop-in) |

| Material Risks | High (Requires Viton) | High (Requires Viton) |

| Legality | 100% Road Legal | Illegal for road use |

| Maintenance | Normal (Check hoses) | Reduced (No DPF clogging) |

📚 Technical References

[1] Engine Performance & Drop-in Capability Zhang, G.D., et al. (2005). “Effect of dimethyl carbonate fuel additive on diesel engine performances,” Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, Vol. 219, No. 7, pp. 897-903.

[2] Anti-Soot Mechanism (GCD/DMC) Mignani, G., & Perret, N. (2016). “Cyclic carbonate derivatives as anti-soot additives for a fuel,” International Patent WO2016012343A1. Solvay / Rhodia Operations.

[3] Glycerol Conversion & Bio-Additives Nda-Umar, U.I., et al. (2019). “An Overview of Recent Research in the Conversion of Glycerol into Biofuels, Fuel Additives and other Bio-Based Chemicals,” Catalysts, Vol. 9, No. 1, 15.

[4] NOx & EGR Interaction Varatharajan, K., & Cheralathan, M. (2012). “Effect of aromatic additives and exhaust gas recirculation (EGR) on NOx emissions of a biodiesel fueled diesel engine,” Fuel, Vol. 94, pp. 310-316.

[5] Material Compatibility & Elastomers Sorate, K.A., Bhale, P.V., & Dhaolakiya, B.Z. “A Material Compatibility Study of Automotive Elastomers with high FFA based Biodiesel,” Sardar Vallabhbhai National Institute of Technology (SVNIT), Mechanical Engineering Dept.

[6] Oil Ash & DPF Plugging Fang, H.L., & McCormick, R.L. (2006). “Impact of Lubricating Oil on Diesel Particulate Filter Performance,” SAE Technical Paper, 2006-01-3271.

Persistent innovation for a sovereign industry.